Data coding system

RFID-打印贴标系统

Printer and automatic labeling technology are integrated and widely used in automatic production packaging line and logistics

During production process, real-time information can be automatically printed and pasted, to avoid human error.

Information is instantly and effectively shown on the tagged object.

The printable real-time information includes: production date, batch number, anti-counterfeiting information, logistics information, sales channel information, bar code and variable information, especially in the application of automatic identification of variable information. The printing information is the real-time information generated automatically by computer communication control or other automatic equipment. LPA system printing and labeling is fully automatic, which improves work efficiency, reliability, instantaneity, accuracy, and saves labor cost.

The embedded thermal transfer printing engine, as the core component, is equipped with industrial computer and megawin special software for control, which is simple and fast in operation, clear in content and clear in prompt

It provides an effective implementation tool for the application of logistics monitoring in various industries. It can print and paste the goods and packaging information, relevant goods code, production and serial number information, transportation information, and sales channel information on the outer carton of the package in the form of text, code and bar code, so as to facilitate tracking in the whole transportation and distribution process

RFID systems

Videos:

What is RFID?

RFID stands for Radio Frequency Identification. This means remote identification by radio frequency. The technology is used by send-receive systems that can automatically and remotely identify or localise objects and living beings. These RFID systems are used in a diversity of fields – in logistics, for instance.

How does RFID work?

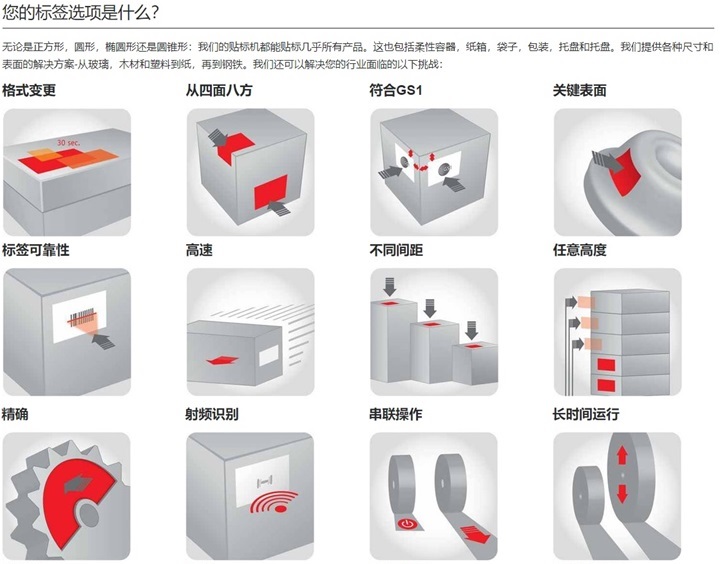

Every RFID system comprises an electronic data carrier (RFID label) and a reader (RFID reader). Both components have an antenna for communication of data. Data is communicated via electromagnetic waves.

The reader generates an AC electromagnetic field. Two-way communication takes place should the transponder be located within range. The reader can now write data to the chip or read data in memory.

What are the advantages of RFID?

Contactless process: Data are transmitted from transponder to reader/writer and vice versa via RF antennae. This requires no physical or visual contact. The RF signals can penetrate various materials. Not only does this allow for faster reading of goods, but it also facilitates reading inaccessible parts.

Fast data exchange: The time delay between transmission and reception is virtually negligible with RF transmission.

Bulk reading: RFID readers are capable of reading large numbers of RFID tags simultaneously. All the products on a pallet or in a shipping container can theoretically be read in a single scanning process.

Virtually error-free: The initial read success of RFID labels approaches 100%. Additional reliability is offered by RFID systems that detect and eject faulty tags.

Security through encryption: Data may be encrypted instead of transmitting in clear text, to allow access control.

Robust: RFID tags are resistant to extreme ambient conditions such as high temperature fluctuations, heat, cold or moisture. Products that will later require special reworking or cleaning may be reliably marked using RFID.

Reusable: As opposed to printed barcodes, RFID chip data can be edited and supplemented later.

Invisible: The tiny RFID transponders may be inconspicuously integrated into most labels.

Where are RFID chips used?

RFID applications are many and varied. The technology is fundamentally suited for automatic marking, identification, registration, storage and monitoring of components or shipping containers. A few examples:

Production control: In industrial manufacturing, RFID chip data may be used to document a product’s production status. Further process parameters may be specified based on this information. This procedure is widely used already, especially in the automobile industry.

Traceability: RFID tags can store all production and source data, allowing unequivocal and complete traceability along the supply chain down to location and time of production.

Inventory management: Libraries use RF labels, among other, to control borrowing and return of media through self-service terminals.

Store management: RFID may be deployed to automatically capture pallets at goods receipt, book them in the inventory control system and transport them to their designated shelf.

Product protection: High-grade branded products use RFID transponders to differentiate between originals and counterfeits during authenticity checks.

Access control and clocking: Many companies use RFID chips for automatic access control at entrances and/or to record staff working hours at designated terminals.

All partners of Megawin Bestow Group, please register on our website

Press "LOGIN"

Apply for your favorite products, and we will open the download permission for you

If you are interested in this product, please leave a message on the website, we will reply you in time!

http://www.megawin.cn/En_Ct_index_gci_10.

若您对该产品有兴趣请微信扫描以下左边二维码,我们专案经理将及时回复您!产品报修请微信扫描以下右边二维码!